Tin Side Detector

TS2300 | Digital Tin Side Detector

Digital Tin Side Detector The digital Tin Side Detector offers a new technology for identifying the tin surface of float glass. This new detector boasts several advantages over traditional bulb-sty..

$265.00

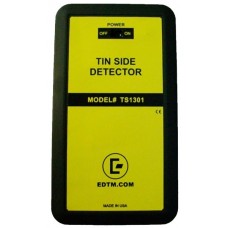

TS1301 | Tin Side Detector Lamp

Tin Side Detector Lamp Our NEW Tin Side Detector (Model# TS1301) allows you to determine the tin side of float glass. The instrument can test clear float glass or glass with other specialty co..

$185.00

TS1310 | Replacement Lamp for Tin Side Detectors

Replacement Lamp for Tin Side Detectors The TS1310 Replacement Lamp is for all the lamp-style Tin Side Detectors from EDTM. Compatible with the TS1301 and TS1320 models...

$35.00

TS1320 | Commercial Tin Side Detector

Commercial Tin Side Detector The Commercial Tin Side Detector (Model # TS1320) incorporates several new features requested by users of previous tin side detector models. The lamp is more..

$224.00

TS1470 | Tin Side Detector - Higher Intensity Glow

Higher Intensity Glow Tin Side Detector The NEW Tin Side Detection Lamp is the perfect solution for brighter-lit environments where it can be difficult to see the glowing tin side of the glass.&nbs..

$799.00

TS1475 | Replacement Lamp for TS1470 Tin Side Detectors

Replacement Lamp for Tin Side Detectors The TS1475 Replacement Lamp is for the lamp-style Tin Side Detector TS1470 from EDTM...

$86.00